Research Article

Research Article

Energy Audit - A Case Study of Switch Gear Manufacturer

Syed Adeel Ahmed Shah* and Sudhir Chitrpaday Vishweshwara

Mechanical Department, National University Science & Technology, Muscat, Oman

Syed Adeel Ahmed Shah, Mechanical Department, National University Science & Technology, Muscat, Oman.

Received Date: June 21, 2022; Published Date: June 29, 2022

Abstract

Keywords:EMS; Energy consumption; Energy cost; Energy audit

Energy Audit - A Case Study of Switch Gear Manufacturer

The procedure for implementing the energy management system in an existing switchgear manufacturing company is presented in this paper. The aim of the paper is to provide a guideline for the implementation of an Energy management system for the conservation of energy at the major energy consumption equipment in a manufacturing facility. The energy management system (EMS) was introduced to a Switch Gear manufacturer using an energy analyzer. EMS was designed to reduce the energy consumption of air conditioning units with the installation of an additional thermostat that was retrofitted to the existing air conditioning unit. The thermostat system was programmable and could be easily interfaced with the air condition systems which were set up at a particular temperature. The thermostat’s main function here was to adjust the temperature of the air condition and regulate the temperature surrounding and function the ac to go on an idle mode if the temperature drops after a certain value which was kept by the comfort zone of the user depending on the climate. The system was further linked to the energy analyzer for continuous monitoring and apprehending a clear picture of the kilowatt-hours. The study results were obtained by the energy audit of the conditioning unit. and lightning systems which consist of a major portion of the asset site usage a vivid analysis was formulated by applying EMS to the asset. By applying the logic of EMS explained previously an amount of 172.96 KW/h is saved in a week’s time which could eventually reduce the energy cost to a minimum of around 168 OMR per year.

Methodology

The energy management system which is applied to the asset works in a very orthodox manner. To start with the rather high consumptions equipment’s are addressed with this system i.e. the lightning and the ac system. They consume a high proportion in the MK Switch Gear. Asset before was functioning in an old fashioned and manual way. The techniques which were applied were rather outdated for example switching off the lights and ac whenever not in use manually [1]. This system when applied to the asset mainly controlled these two problematic areas. We developed a logic programming to address energy consumption. The prime focus was kept on the lunch hours and tea break hours. Timing was setup with alignment of the lunch break hours and the tea break hours for the lightning system as well as the ac system for the switching off and regulating this equipment’s automatically. At times during these periods switching off light were missed via applying this system the human error of forgetting the switching off was completely eliminated. The system was further linked to the energy analyzer for the continuous monitoring and apprehending a clear picture on the kilowatt hours. Secondly a thermostat was introduced in the programming for the air condition systems which was setup on a particular temperature [2].

Thermostat main function here was to adjust the temperature of the air condition and regulate the temperature surrounding and function the ac to go on an idle mode if the temperature drops after a certain value which was kept by the comfort zone of the user depending on the climate .Asset was functioning before without a thermostat and the ac load was continuous on where consumption was rather on the upscale as shown in the above results attained by energy audit.. Lastly to address the functioning of ac in the normal working hours a logic cycle was created of functioning half of the ac in one cycle and the latter in the rest cycle. Here in the asset 7 air-conditions were running so the cycle was divided into 4 and 3 respectively .The cycle was also created in consideration of the office hours (8 to 5) .The cycle was created to help the asset recover the energy consumption as well reduce the maintenance issue and thereby increasing the life cycle of the ac as well. The logic behind this design is explained in appendix.

Results & Discussions

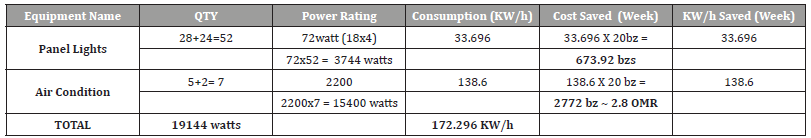

When energy management system was applied to the asset, especially on the focused timings and areas the following table depicts the results. These results are evaluated from lunch break and tea break (Table 1).

Table 1:Analysis on MK Switch Gear after Application of EMS.

As per the results obtained by the energy audit of AC and

lightning systems which consist of a major portion of the asset site

usage a vivid analysis was formulated by applying EMS to the asset.

Through applying the logic of EMS, a grand amount of 172.96 KW/h

is saved in a week time which could eventually reduce the energy

cost. This would further reduce the energy consumption and reduce

the bills of the asset in the months to come [3].

Energy cost reduced in a year time would be:

Energy cost in a week: 172.296 X 20bz = 3445.92 ~ 3.5 OMR

Energy cost saved in a year: 3.5 X 48 = 168 OMR

These are the results by applying the EMS on this particular equipment. The horizon could be expanded and done with the other equipment for a better outcome in saving point of view for the MK Switch Gear asset. The values attained by this logic is not that much in the amount of money as MK Switch gear asset is rather a smallscale industry among the MK divisions. It can be further added that since the figures reflect small scale setup it can be imagined that on a large scale how much can be fiscal saving can be achieved by applying EMS systems.

Conclusion

Energy management system which was introduced to the asset helped in reducing the energy consumption and the logic which was developed helped in the problematic areas of Ac and lightning system. The Energy management system logic which was applied to the Ac and lightning systems gave the saving of 172.296 KW/h per week. Which further if converted in cost would save almost 3.5 OMR weekly. Energy management system with the help of energy analyzer could help to monitor the rest consumptions in real time which could further help in reducing the energy consumptions.

Recommendations

To have more advanced approach to energy management systems a device can be introduced to the asset in the future goes by the name of power tag. This particular device is a compact and user friendly with a multi-function to measure energy and power simultaneously and in real time. The energy sensors which are installed in the device gives the signals wireless to the user by email or through the app so the user can check which device should be monitored. The asset can check the alerts of any electrical upsurge of the high consumption devices and take actions accordingly to conserve energy in real time which can be beneficial in the long run of the asset. The management can find a drastic change in the efficiency before and after the integration of the device. The device alerts by alarms and of any fluctuations in the energy consumptions. Lastly the device is eco-friendly and is feasible in the footprint sections.

Acknowledgement

None.

Conflict of Interest

No conflict of interest.

References

- Schneider Electric (2022) PowerLogicTM PowerTag. Schneider Electric Global.

- Syed Adeel Ahmed Shah (2019) Energy Audit for and office and workshop A coursework submitted to National University Science & Technology for the module Energy Audit and Asset Management : National University Science & Technology Oman.

- Sajjad SM (2021) Mustafa & Kamal Ashraf.

-

Syed Adeel Ahmed Shah, Sudhir Chitrpaday Vishweshwara. Energy Audit - A Case Study of Switch Gear Manufacturer. Glob J Eng Sci. 9(5): 2022. GJES.MS.ID.000722.

-

EMS, Energy consumption, Energy cost, Energy audit

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.